xTAG Vibration Sensors are used to monitor the operation of heavy industrial equipment and support forecasting failures before they happen - helping operators avoid costly unplanned shutdowns.

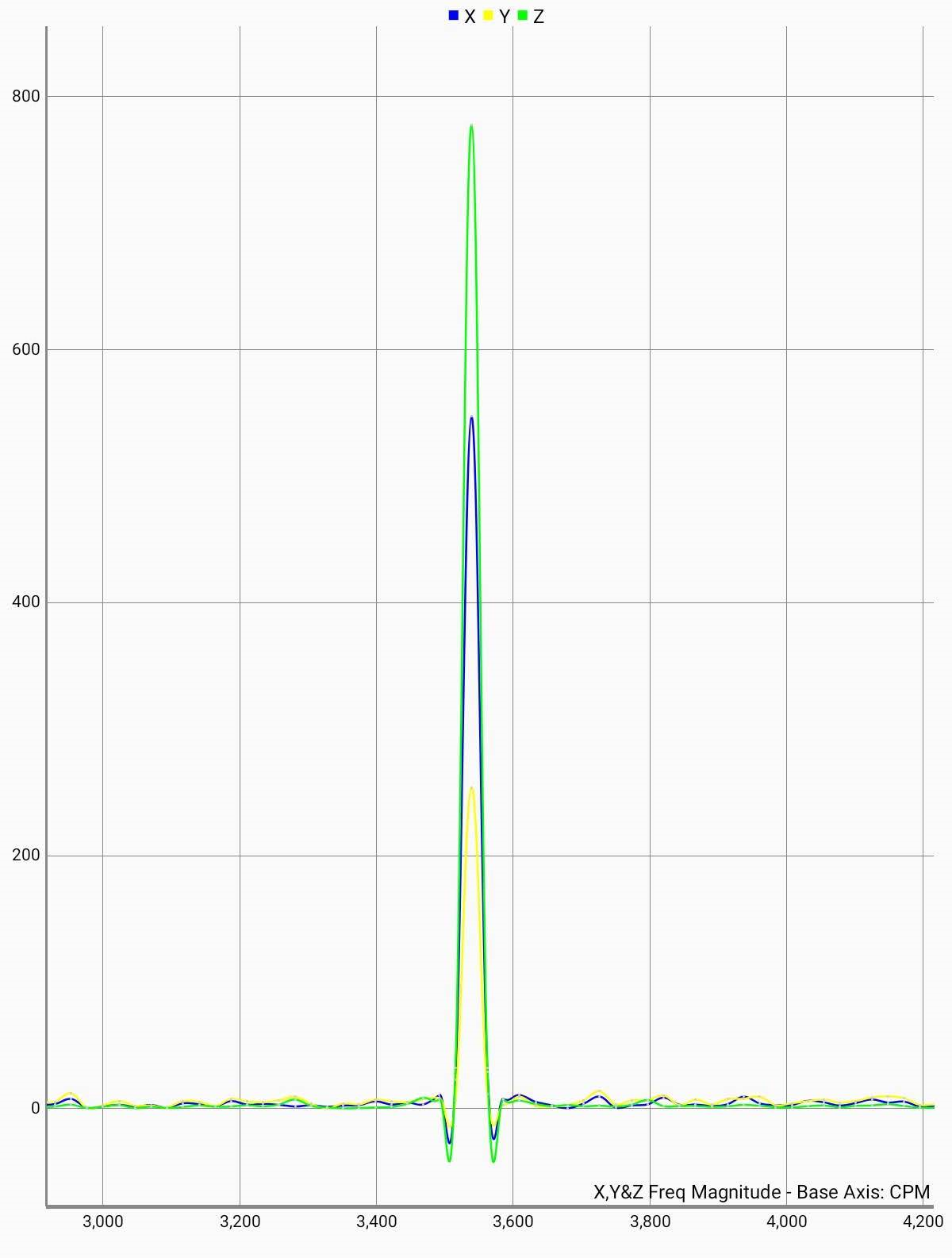

xTAG Wireless Vibration Sensors can be used to diagnose machine health whenever operators need an update. Operators can carry magnetic mount xTAGs, position them on a machine, connect to the xTAG using a tablet app, start a data acquisition stream to a real-time chart in the app and then review detailed data reports. To compare current data to previously acquired data, raw data exporting and report chart exporting is supported. This use of xTAG Wireless Vibration Sensors is the easiest option for operators to get started in monitoring machine health to ensure machines don't cause costly production interruptions.

To access consistently updated machine health reports from anywhere with an internet connection, permanently install a wireless xTAG Wi-Fi (HaLow) Vibration Sensor or a wired xTAG USB Vibration Sensor on machinery. Install xGATEWAYs near xTAGs and connect xTAGs to them in minutes. xGATEWAYs are pre-installed with software that can be quickly configured to push data to the Microsoft Azure IoT cloud, or to a local data repository if required (or both). Reporting is available through Azure IoT. Amazon Web Services (AWS IoT Core) or Google Cloud Platform (GCP) support is also available.

The xTAG Vibration Sensor supports high-speed vibration data acquisition (25 to 1600 samples per sec in X, Y and Z dimensions). Additionally, it supports gyroscopic angle sensing at the same sample rate (current orientation in 3 dimensions). Acquired data can be used to determine machine on/off status or to forecast machine failures - dramatically reducing costs associated with unplanned downtime. The wireless xTAG Vibration Sensor has been designed to draw very little power from its battery during normal operation. When sensing “part time”, it is capable of collecting vibration data for many years (replaceable battery lifespan depends on daily acquisition frequency, duration and sampling rate). The xTAG can be set up to collect samples based on machine activity. For example, collect samples for a set duration every time a machine starts. In this context, an xTAG Vibration sensor battery life of 5 or more years is possible.

xTAG Ventilation Sensors can substantially increase the safety of public and private spaces while ensuring that ventilation systems do not waste expensive energy.

Contact [email protected] for more information on how xTAG Ventilation works.

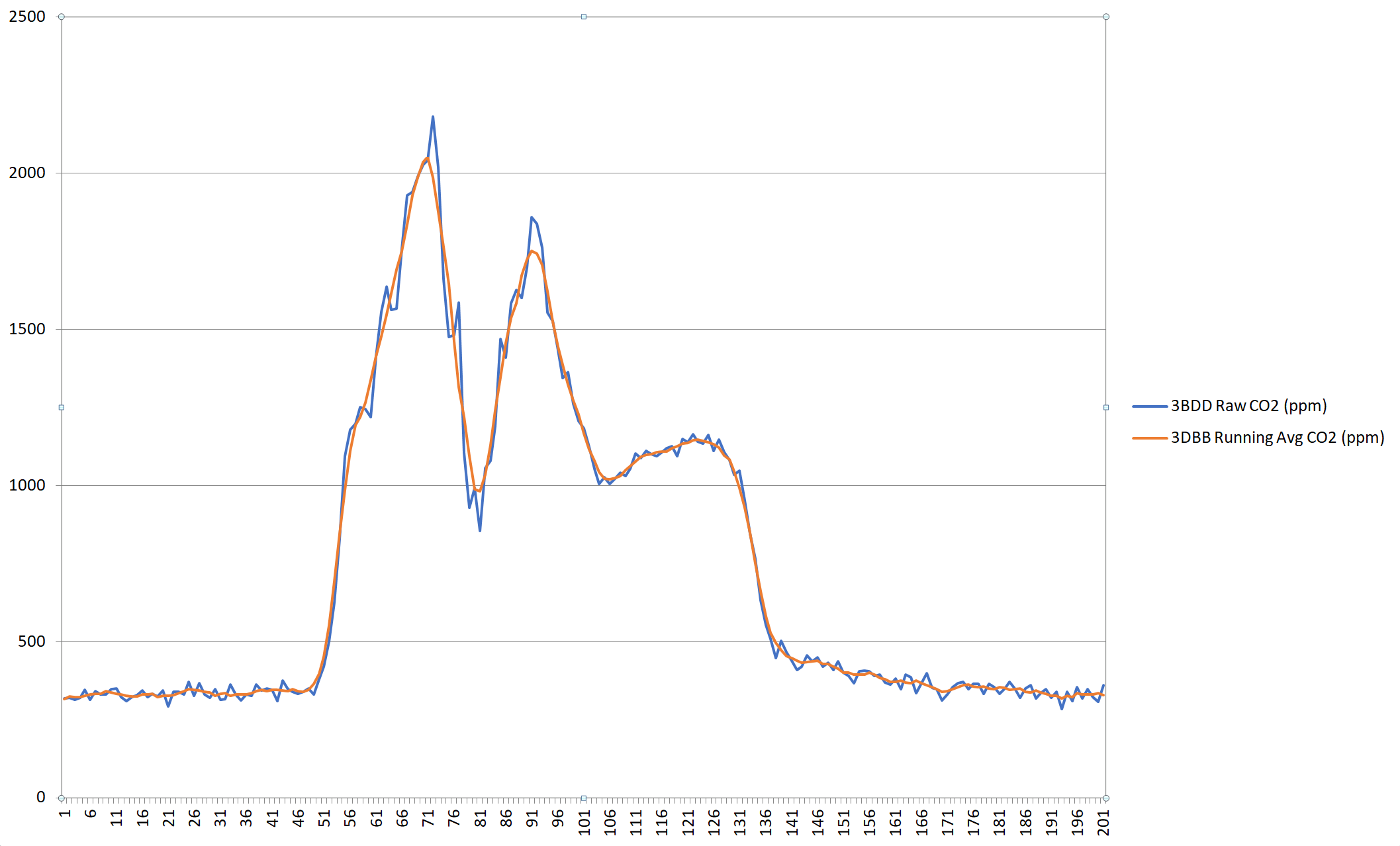

Our new xTAG Wireless Ventilation Sensor has been deployed within a trial. CO2 was measured within a Canadian school every 5 min and sensor data was collected using our xTAG Explorer App on a Tablet with wireless support. The trial effectively tracked the concentration of CO2 through the course of several weeks. A typical day's data is shown below.

Ambient CO2 commonly stays at 400ppm when room is empty. This samples where taken before the school day begin shows consistent CO2 levels. As the school day progresses, the CO2 levels increase. Ventilation can reduce the concentration throughout the day depending on the capacity of the rooms. The chart provides evidence that ventilation can be increased.

xTAG Ventilation Sensors can substantially increase the safety of public and private spaces while ensuring that ventilation systems do not waste expensive energy.

Monitor machine health by sensing when parts become overheated, when air filters become fouled by measuring filter pressure differential or when any other abnormal temperature or pressure is observed. Avoid costly breakdowns and production interruptions.

Monitor produce exposure to high temperature and humidity and trigger alarms or log events that can be used to explain spoilage during shipping. Keep produce fresh and hold shippers to account for failed shipments.

Keep pets and livestock safe by sensing their exposure to high temperature and humidity. Alarm when action is required and an animals safety is at stake.

Ensure that workplaces are operating at optimum temperature and humidity to discourage the growth of mold and keep workers comfortable and productive.

Product quality can often be affected by its production environment. Ensure that production lines are kept at optimum temperature and humidity.

xTAG Gas Sensors measure the concentration of Volatile Organic Compound (VOC) and Volatile Sulphur Compound (VSC) gases in air. There are a vast array of measurable VOC/VSC gases including sewage gas, propane, natural gas (methane), construction off-gases, fire off-gases

The xTAG design has been created to support additional sensing options through a simple substitution of its front membrane. A variety of sensor chips can be added to this membrane that also includes a pushbutton and LED. Membrane substitution examples:

Hall effect sensing. Count machine shaft rotations or measure machine current draw through magnetic field measurements.

Color sensing. Sense installed color alarm states or track produce health.

Sound sensing. Listen for machine status (dB level) or mechanical issues (dB level or frequency).

xTAGs are available in three variants. The xTAG Wi-Fi HaLow (802.11ah) Sensors support long range connectivity of thousands of xTAGs to a single xGATEWAY. These options facilitate the simplest possible xTAG installs where xTAGs won’t require local power. In some installations, wireless just won’t work effectively due to excessive Sensor power draw (due to high sample rates), electromagnetic noise, or physical barriers between xTAGs and xGATEWAYs. When wireless is a challenge, select the xTAG USB Sensor variant for reliable 12 Mbit/sec communications between USB-powered xTAGs and xGATEWAYs.

Regardless of the variant selected, all xTAGs are accessible to xGATEWAYs without xTAG configuration. This is sometimes referred to as “zero configuration networking” or “plug-n-play”. Complex addressing of devices is never required. xGATEWAYs can automatically discover all xTAG wirless devices nearby and a physical connection to an xTAG USB is all that is required before an xGATEWAY can access its data.

85 g or 3 oz.

50mm (2”) wide, 68mm (2.5”) long, 42mm (1.5”) tall

xTAG Wi-Fi (HaLow): 802.11ah with selectable tx power and phy (up 1 1km range and 500kbps-2Mbps)

1 to 8 year battery life depending on sensor variant and acquisition frequency

xTAG USB: USB-powered device at 12 Mbps with 5m+ cable length (up to 100m with USB extension)

Screw-in flange or magnetic-mount options

IP67 dust/water ingress rating

-40°C to 70°C operating temperature