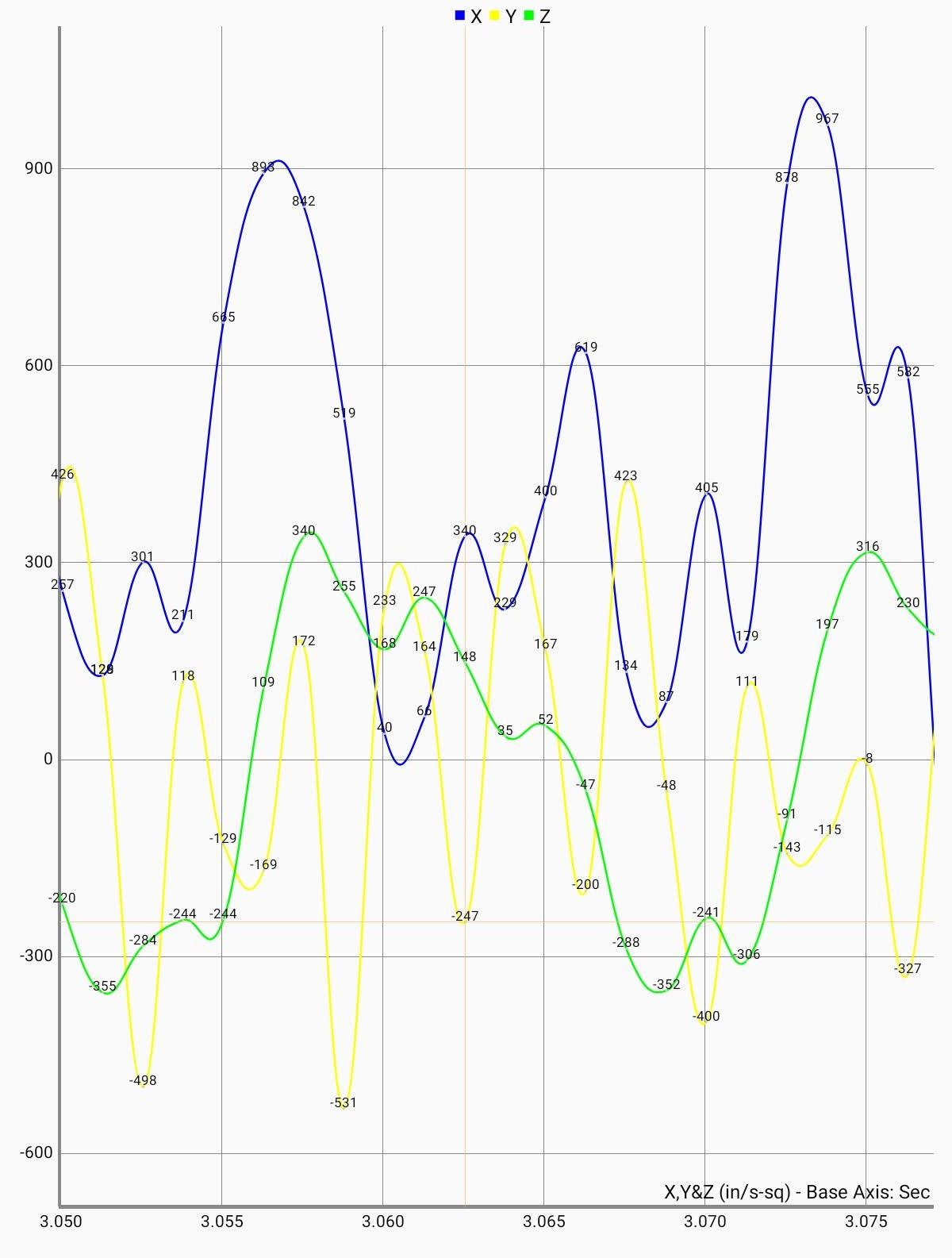

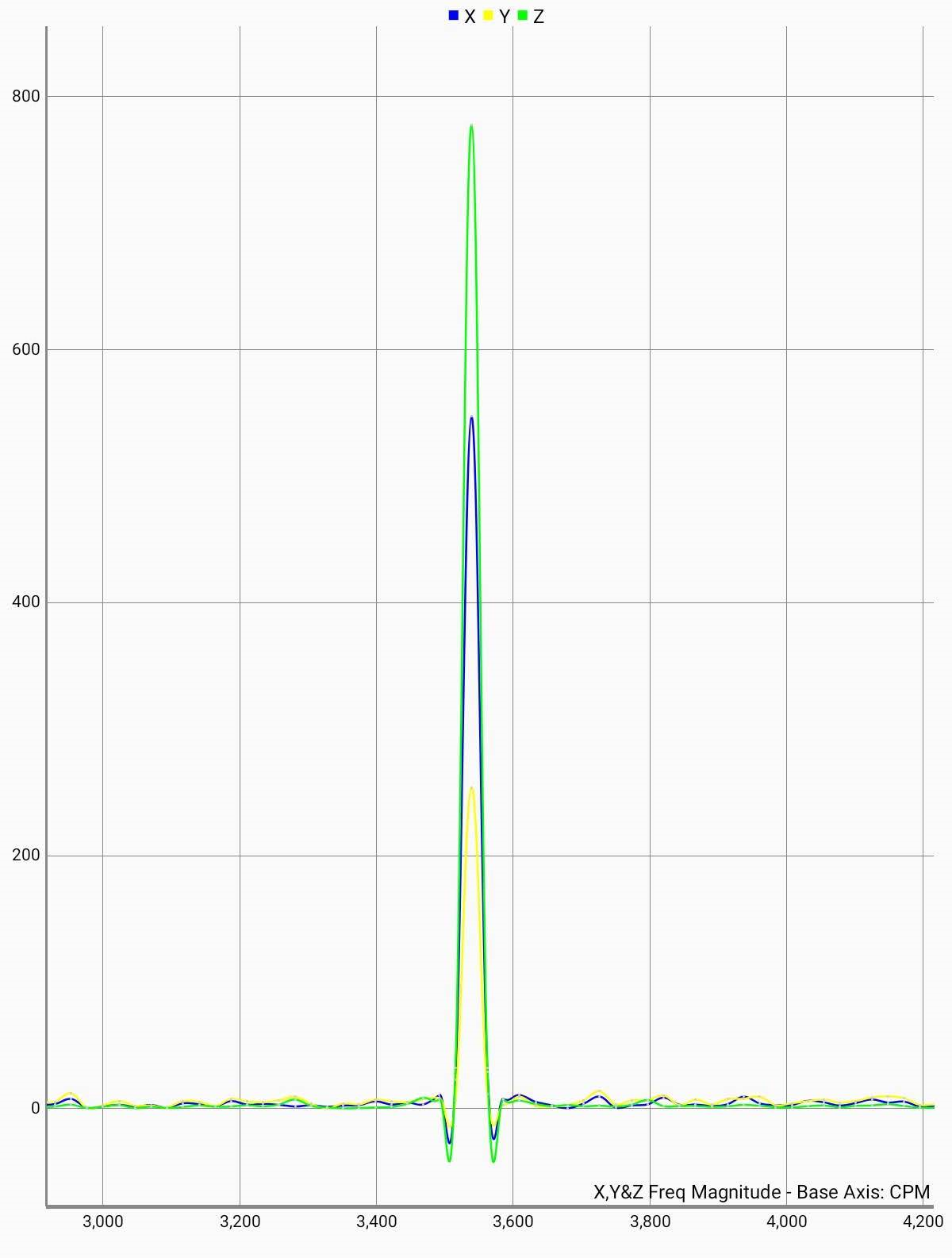

The Deviceworx xTAG Sensors support high-speed vibration data acquisition (25 to 1600 samples per sec in X, Y and Z dimensions). The acquired data can be very effectively analyzed to forecast machine failures - dramatically reducing costs associated with unplanned downtime.

The wireless xTAG has been designed to draw very little power from its battery during normal operation. When sensing “part time” (ie. only after each machine start), it is capable of collecting vibration data for many years (replaceable battery lifespan depends on daily acquisition frequency, duration and sampling rate).

xTAG wireless sensors can be used to diagnose machine health whenever operators need an update. Operators can carry magnetic mount xTAGs, position them on a machine, connect to the xTAG using a tablet app, start a data acquisition stream to a real-time chart in the app and then review detailed data reports. To compare current data to previously acquired data, raw data exporting and report chart exporting is supported. This use of xTAG wireless devices is the easiest option for operators to get started in monitoring machine health to ensure machines don't cause costly production interruptions.

To simplify diagnostics further, operators can permanently mount xTAG wireless devices on machinery and simply connect to them using the tablet app when a machine health update is required.

The xTAG Explorer app is available from the Google Play Store

Keep machines operating to avoid unplanned production stoppage & dramatically save on operating costs.

Microsoft Azure connections are completely secure using best practices developed to serve extra sensitive manufacturing and industrial facilities. The new xTAG LTE includes a Trusted Platform Module with TPM 2.0 support to add hardware-level security to the xGATEWAY.

Automatically archive data and generate reports on the cloud or locally.

Adaptive data modeling and comparison can be used for automatic discovery of machine faults.

Trigger alarms in the form of text messages or emails whenever a vibration data threshold is breached.

Leverage the xGATEWAYs ability to interface to existing instrumentation or controls to combine other data points (e.g. bearing temperature, drive speed ...) with vibration data for enhanced monitoring.

To access consistently updated machine health reports from anywhere with an internet connection, permanently install xTAG wireless or xTAG USB wired sensors on machinery. Install xGATEWAYs near xTAGs and connect xTAGs to them in minutes. xGATEWAYs are pre-installed with software that can be quickly configured to push data to the Microsoft Azure IoT cloud, or to a local data repository if required (or both). Reporting is available through Azure IoT. Amazon Web Services (AWS IoT Core) or Google Cloud IoT support is also available.